The Internal Floating Roof is a crucial component for optimizing the performance and safety of storage tanks. Positioned inside the tank, this roof floats on the liquid surface, providing a barrier that significantly reduces vapor emissions and evaporation losses. By minimizing the tank's exposure to the atmosphere, it enhances product quality and compliance with environmental regulations. The Internal Floating Roof also improves operational efficiency by minimizing maintenance needs and preventing contamination. Available in both full contact and non-contact designs, it is adaptable to various storage requirements, offering a reliable solution for managing volatile and valuable materials.

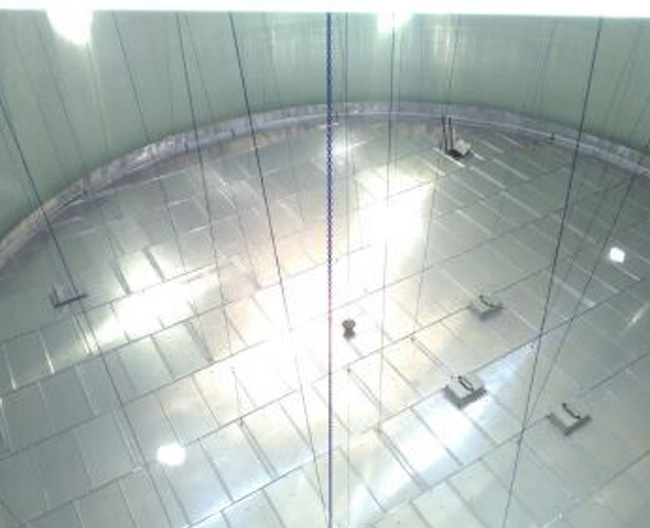

Full Contact Internal Floating Roof

Designed to rest directly on the liquid surface, the full contact internal floating roof offers excellent vapor control and minimizes emissions by maintaining a tight seal. Its continuous contact with the liquid reduces evaporation losses and enhances tank safety. Ideal for volatile or sensitive materials, this type provides optimal performance in preventing contamination and maintaining product quality.

Non-Contact Internal Floating Roof

The Non-Contact type Internal Floating Roof maintains a gap between the roof and the liquid surface, using a series of support mechanisms to ensure stability. The non-contact design facilitates easier maintenance and inspection of the tank interior while still offering effective vapor control and emission reduction. Suitable for a range of storage applications, it balances operational efficiency with ease of access and lower maintenance requirements.